Step 1:

Material Sourcing and Eco-Friendly Lamination

We start by sourcing eco-friendly, plant-based materials from trusted suppliers. Unlike traditional packaging with three layers, our approach involves using only two layers - one that touches the food, and the other for printing and coating on the outside. This not only reduces material usage by up to 30% but also ensures all our film arrives pre-laminated, reducing the risk of chemical contamination on the food-safe layer.

Step 2:

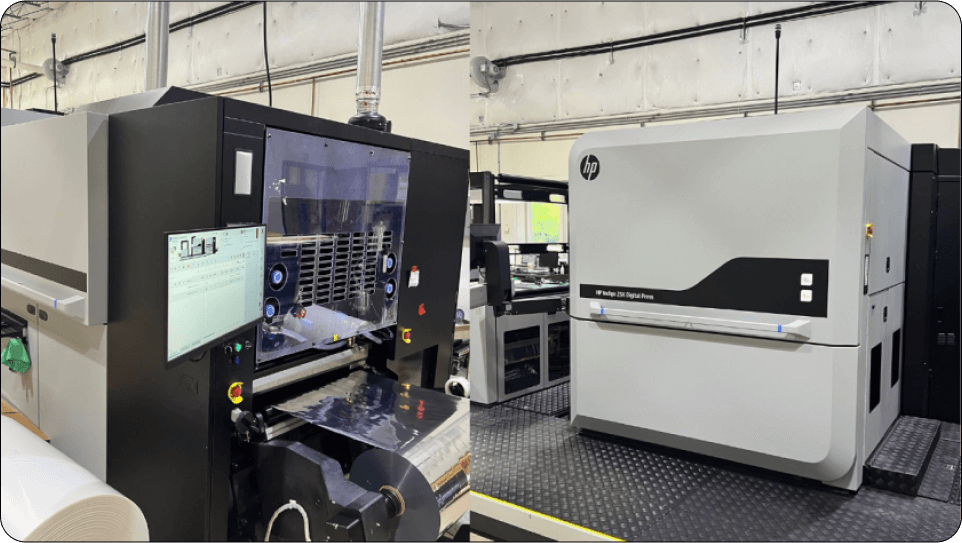

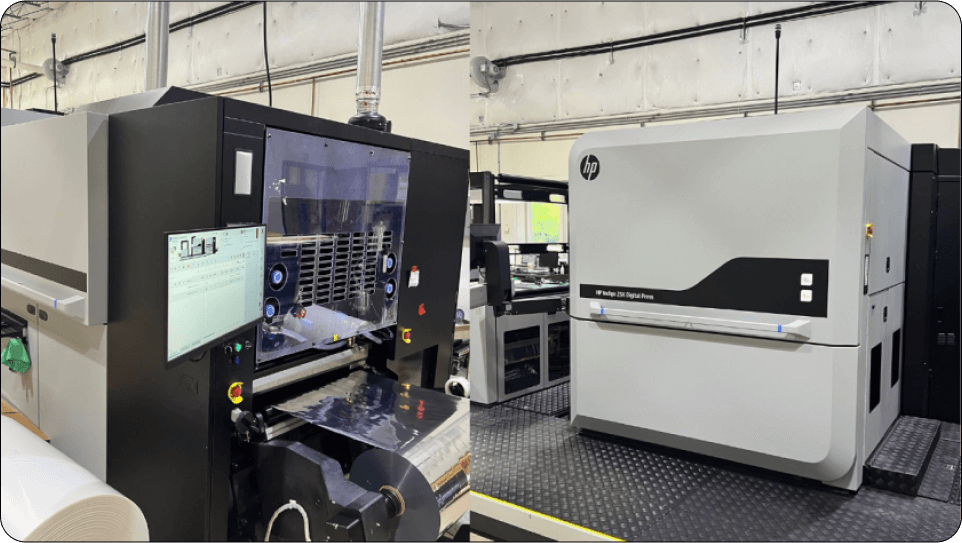

Environmentally Conscious Printing and Customization

Our printing process is environmentally friendly, using water-based inks instead of dyes. We also use a closed-loop printing system to reuse excess inks. The entire printing process is enclosed in a shell which prevents air particles from interfering with the inks. Additionally, we eliminate the need for printing plates, allowing for faster production times and greater design flexibility. With variable data printing, you can easily customize each design to suit your needs - aka, infinite SKU potential.

Step 3:

Safe Coating and curing

We use a water-based varnish for scratch resistance and employ electron curing instead of chemicals, making it safer for everyone.

Step 4:

Slitting

We cut the rolls into smaller ones to separate different orders.

Step 5:

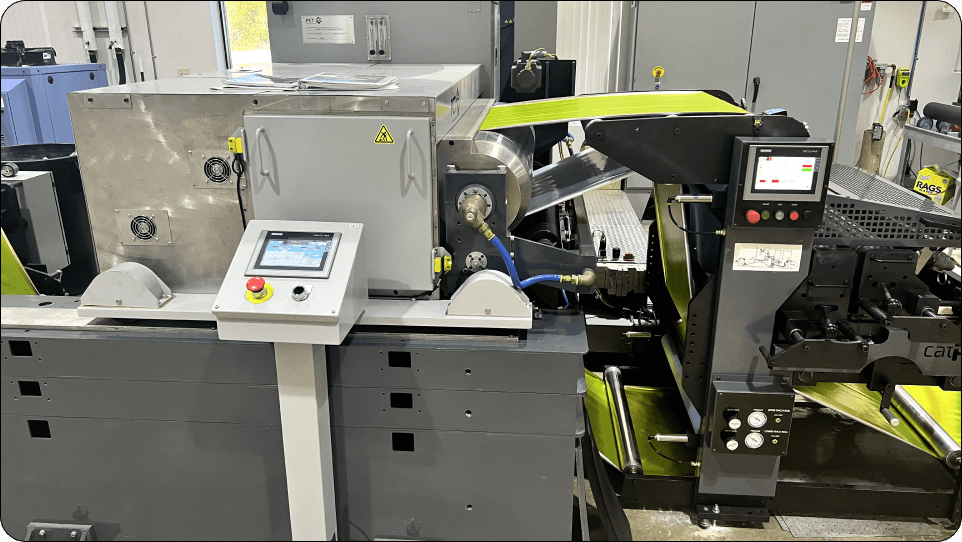

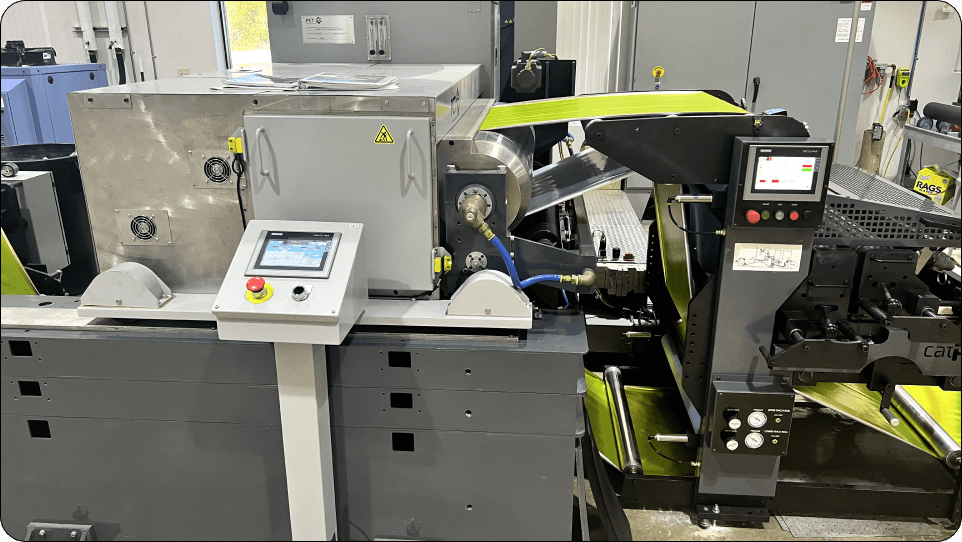

pouching

We place smaller rolls on the pouching line and ensure the pouches have strong seals by testing pouches at random intervals in our specialized water tank.

Step 6:

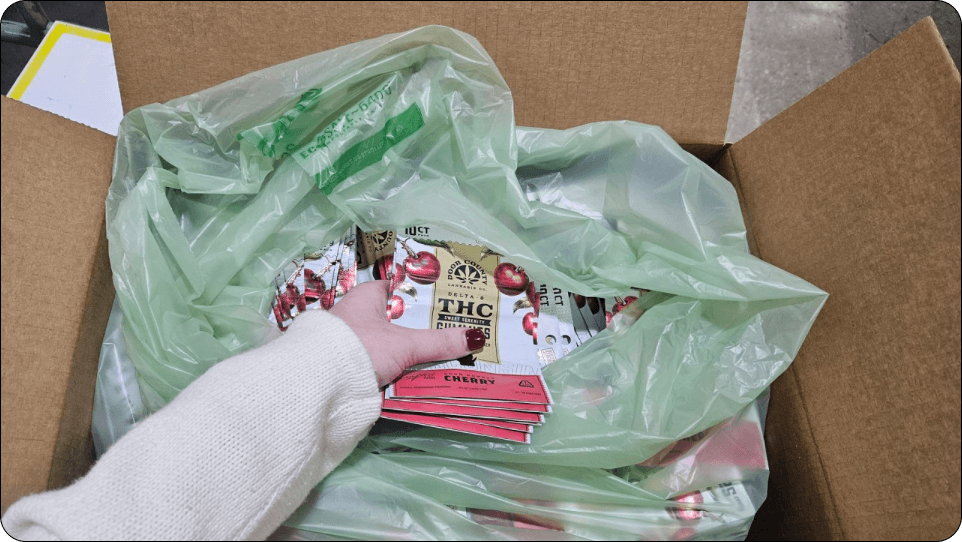

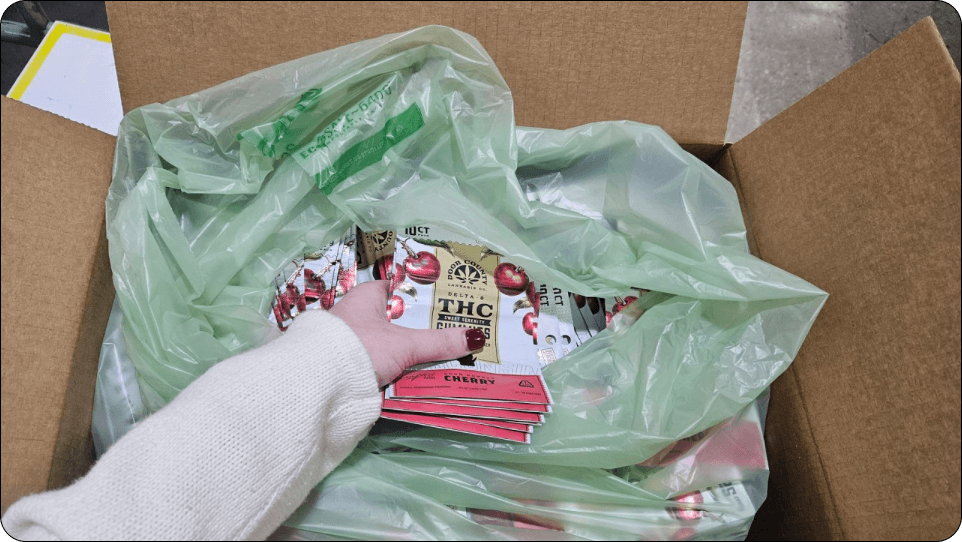

shipping

We package each order in compostable bags for food safety before boxing them up or placing them on pallets.

Step 7:

Composting (Lomi and Break it Down Austin)

In addition to individual material certifications, we test our materials in-house for compostability by placing finished pouches (zippers, valves, and all) in our Lomi composter and running a cycle. This enables us to check for degradability in hours rather than months. Additionally, any other waste materials made during production are captured and sent to our composting partner (Break it Down Austin) to be processed into dirt.

Login and Registration Form